In the ever-evolving world of construction, efficiency, safety, and durability remain top priorities for builders and contractors. Among the numerous tools and materials available today, pneumatic deck nails have emerged as a game-changer in decking and outdoor construction projects. These nails, when used with pneumatic nail guns, offer unmatched speed and precision, making them a popular choice for both professionals and DIY enthusiasts.

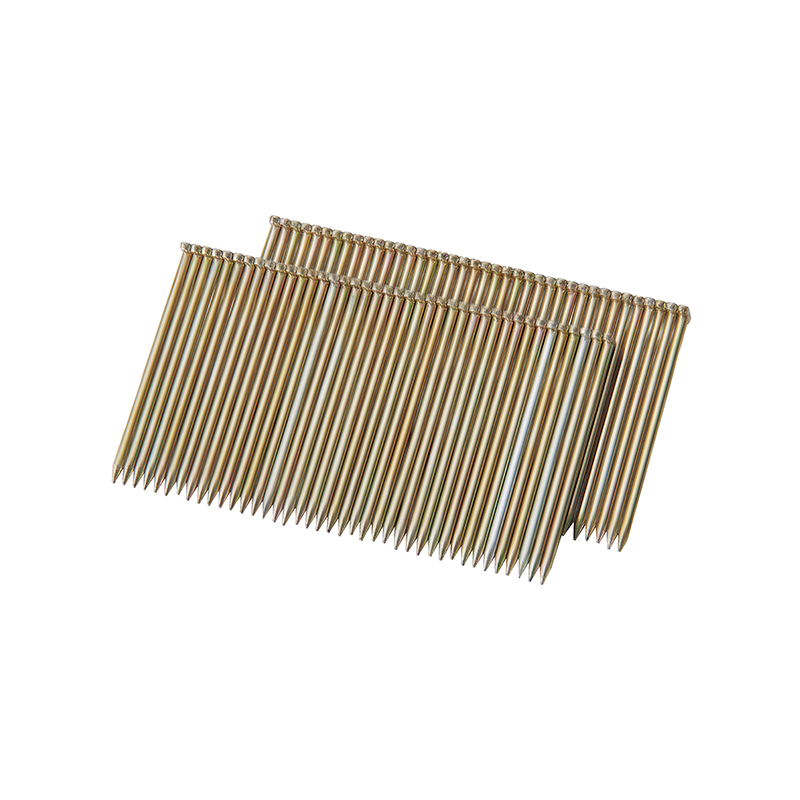

Pneumatic deck nails are specifically designed for use with air-powered nail guns, also known as pneumatic nailers. These nails are manufactured to exact specifications to ensure consistent performance under the pressure and rapid firing speed of pneumatic tools. The result is a secure, clean, and professional finish that is difficult to achieve using traditional hammer-and-nail methods.

One of the major advantages of using pneumatic deck nails is the time savings they provide. Manually hammering thousands of nails into a deck can take several days, depending on the size of the project. In contrast, a pneumatic nailer loaded with pneumatic deck nails can drive hundreds of nails per hour with minimal physical effort. This increased efficiency not only speeds up project timelines but also reduces labor costs.

In addition to efficiency, pneumatic deck nails contribute to improved structural integrity. These nails are designed to penetrate deep into decking materials, anchoring them securely to the underlying framework. This strong bond ensures that the deck can withstand heavy foot traffic, environmental exposure, and seasonal expansion and contraction. Many pneumatic deck nails also feature ring shanks or spiral threads that increase holding power and prevent nails from backing out over time.

Durability is another key factor that sets pneumatic deck nails apart. Most of these nails are coated with weather-resistant materials such as galvanized or stainless steel to prevent rust and corrosion. This is especially important for outdoor structures, where moisture and temperature changes can quickly degrade unprotected fasteners. With pneumatic deck nails, builders can trust that their decks will remain secure and visually appealing for years to come.

Another often-overlooked benefit of pneumatic deck nails is the consistent quality of their application. When driving nails manually, even experienced builders may occasionally misalign or bend a nail, pilot to weak spots in the structure. Pneumatic nailers virtually eliminate this issue by delivering uniform force and depth with each shot. This consistency ensures that every nail contributes to the overall strength and appearance of the deck.

While pneumatic deck nails are a powerful tool in the hands of professionals, they also make larger projects more accessible to homeowners. With a rented or purchased pneumatic nail gun, homeowners can tackle their own deck installations or repairs, saving money and gaining a sense of accomplishment. However, it is crucial to choose the correct type and size of pneumatic deck nails for the specific decking material and environmental conditions to avoid future issues.

Despite their many advantages, proper safety precautions must be followed when working with pneumatic nailers and pneumatic deck nails. Eye protection is essential to prevent injury from flying debris or misfired nails. Users should also ensure that the air compressor and nail gun are properly maintained and used according to the manufacturer’s guidelines.

Pneumatic deck nails have become an indispensable component of modern deck construction. Their ability to provide fast, durable, and consistent fastening makes them the preferred choice for many builders. Whether you're constructing a backyard deck, installing a boardwalk, or framing a gazebo, the use of pneumatic deck nails can significantly enhance the quality and efficiency of your project. As technology continues to advance, these specialized fasteners will likely evolve further, but their core benefits will remain vital to the future of outdoor construction.

English

English русский

русский 中文简体

中文简体 عربى

عربى

Quick Links

Quick Links